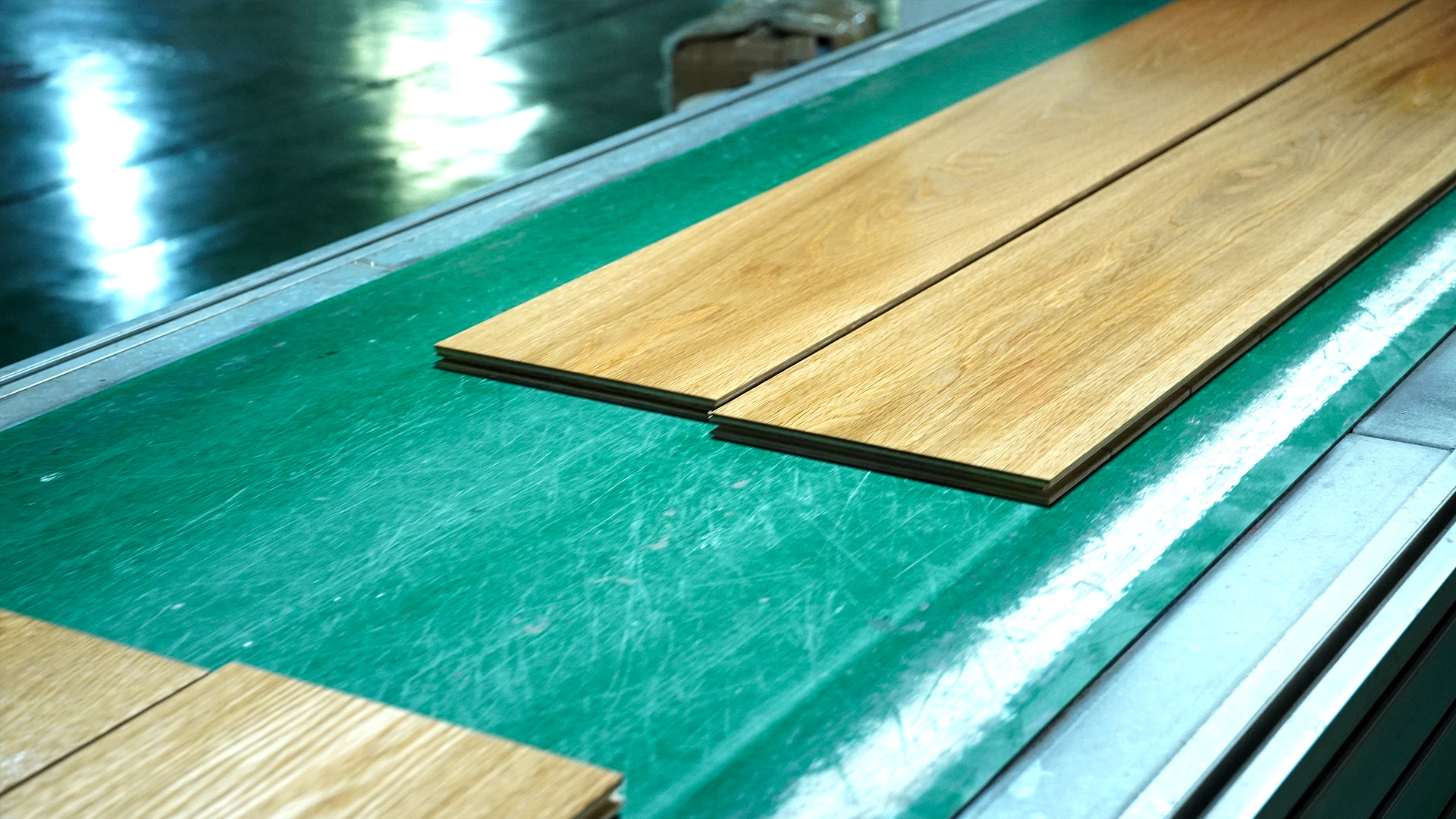

3-layer or multi-layer engineered wood flooring, which one should you buy? It depends on your project budget, end-customer preferences, deliver time, shipping time, quality and warranty etc.

We are a multi-layer engineered wood flooring manufacturer, we think multi-layer engineered flooring is better than 3-ply engineered flooring if you care more about quality than price. If you are sensitive to price and want to buy cost-effective product, 3-layer and multi-ply engineered with thin veneer are both good options.

Of course, you can import both of these kinds of flooring if necessary.

Let get start.

Please note that:

“Sometimes multi-layer engineered wood flooring with veneer plus plywood structure” is also called 2-layer engineered wood flooring on the market.

“Multi-layer engineered wood flooring with veneer and plywood plus oak or larch bottom layer structure” is also called 3-layer engineered wood flooring on the market.

3-layer engineered wood flooring

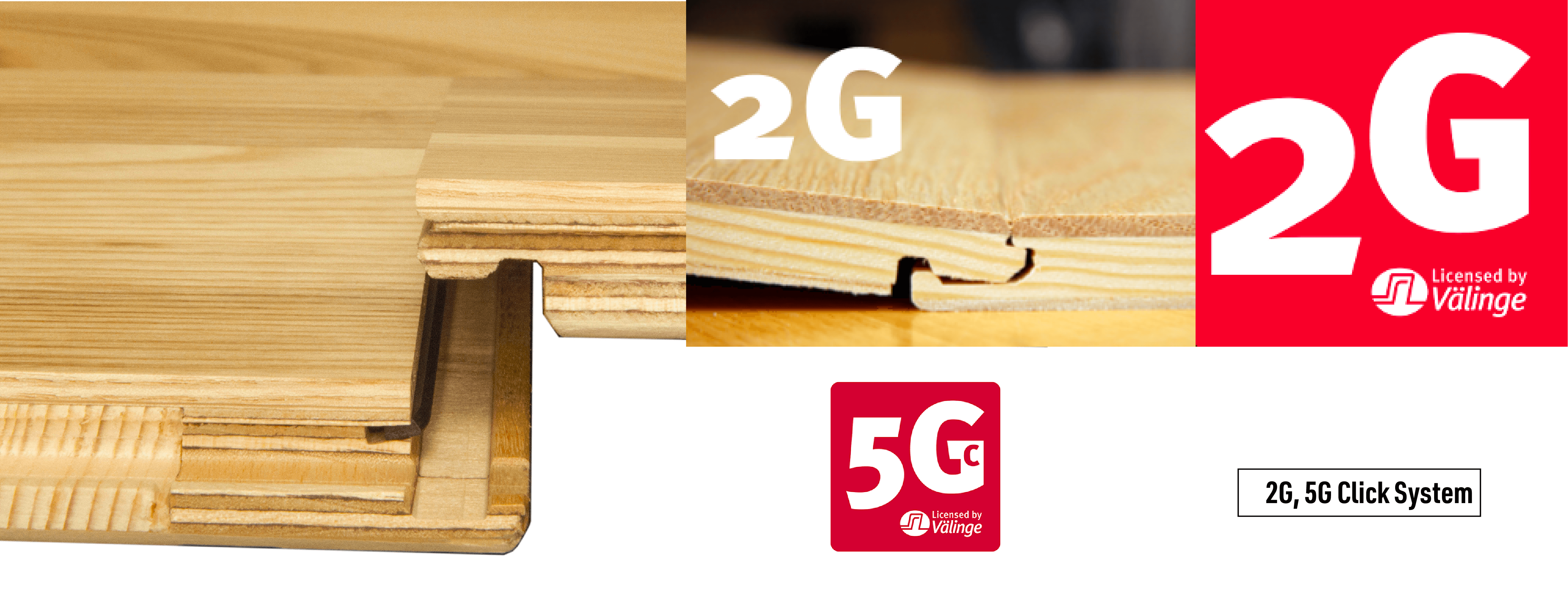

3-layer is made of 3 separate pieces of wood, they are veneer, middle(core) layer and bottom layer. Veneer and bottom layer are aligned with same wood grain direction, middle layer run opposite veneer and bottom layer, which can prevent wood moving and make wood flooring stable.

The middle layer is made up of one single piece of wood, not solid hardwood but softwood and sometime it’s also not plywood, but actually plywood dust consolidated into a block. Because of this, the floor isn’t very durable or resilient and will often expand or contract when the temperature of your home changes. This could result in your floors cracking, cupping, or become otherwise damaged. In China, top layer of the floor in general is 3-6mm oak with sawn cut, 9mm core layer of softwood pine or fir and 2mm backing poplar layer to achieve durability and stability for the floor.

Pros

- Wood grains run in opposite directions through the layers, making floor stable, durable and moisture-resistant.

- Price is cheaper than multi-layer engineered flooring or almost same.

- Top layer is durable with thickness of 3-4mm, can be sanded or refinished 2-3 times.

Cons

- Sometimes just softwood plywood dust, not solid hardwood or hardwood plywood

- More susceptible to moisture damage compared with multi-layer engineered flooring

- More susceptible to warping with temperature changes compared with multi-layer engineered flooring

Multi-layer engineered wood flooring

Multi-layer engineered wood flooring is made from veneer and plywood, plywood is made with cross-grained construction of birch or eucalyptus glued together under high pressure. Multiple layers of plywood running opposite directions create a grid of reinforcement to prevent the wood from moving and allow veneer and plywood expanding and contracting at the same rate to avoid flooring cupping, bowing etc. The plywood also makes the floor more resistant to the moisture and dimension stable. Because of this, with cross-grain construction, multi-layer engineered wood flooring can support longer length and wider width plank floorboards.

Pros

- More suitable for basements, conservatories or rooms that may be humid or damp

- Suitable for under floor heating

- Offering a larger variety of textures, looks and finishes to suit more tastes and needs

- Installation is easier and cheaper than Solid Wood

- Supporting longer length and wider width of plank floorboards

- Offering floating, nailing and gluing down installation methods

Cons

- Price is comparable to solid hardwood and 3-layer engineered wood flooring

- Still not suitable for high moisture environment and water damange

- Potential for VOCs or fading with low-quality flooring

In order that you can get know more about 3 layers and multi-ply structures, we will list difference between them according to our business experience.

Flooring specifications comparison:

Multi-layer engineered wood flooring can support more ranges of dimensions than 3-layer engineered flooring because cross-construction plywood is more dimension stable, durable and moisture resistant than 3-layer middle and bottom layer.

| Types | Multi-layer | 3-Layer |

|---|---|---|

| Wood Species | Oak, Walnut, Teak, ASH, Acacia, Hickory | Oak, Walnut, Birch, Hickory |

| Veneer Grade | AB, ABC, ABCD, CDE, CD, EF | AB, ABC, ABCD, CDE, CD, EF |

| Length | 300-5000 mm | 300-1900 mm |

| Width | 70-400 mm | 90-190 mm |

| Veneer Thickness | 06, 0.8, 1.0, 2, 3, 4, 5, 6 mm | 3, 4, 6 mm |

| Total Thickness | 10, 11, 12, 14, 15, 16, 18, 19, 20, 21 mm | 14, 15 mm |

| Plywood | Eucalyptus, Birch, Pine, Pine+Poplar | Pine, Poplar, Fir |

3-layer engineered wood flooring popular specifications:

3, 4, 6mm sawn cut veneer. French oak, floating and glue down installation.

- 1200 * 120 * 14/3 mm

- 1900 * 190 * 14/3 mm

- 1900 * 190 * 15/4 mm

- 1900 * 190 * 20/6 mm

- 2200 * 220 * 14/3 mm

- 2200 * 220 * 15/4 mm

- 2200 * 220 * 20/6 mm

- 2200 * 260 * 14/3 mm

- 2200 * 260 * 15/4 mm

- 3000 * 300 * 20/6 mm

Multi-layer engineered wood flooring popular specifications:

2mm sliced cut veneer, 3, 4, 5, 6mm sawn cut veneer. Russian oak, French Oak, walnut.

10/2 mm thickness.

- 600 * 90 * 10/2 mm

- 910 * 125 * 10/2 mm

- 910 * 125 * 10/2 mm

- 900 * 120 * 10/2 mm

10/3 mm thickness.

- 600 * 90 * 10/3 mm

- 900 * 90 * 10/3 mm

- 900 * 120 * 10/3 mm

- 1200 * 150 * 10/3 mm

- 1900 * 150 * 10/3 mm

10/4 mm thickness.

- 600 * 70 * 10/4 mm

- 900 * 90 * 10/4 mm

- 600 * 90 * 10/4 mm

- 800 * 90 * 10/4 mm

13/3 mm thickness.

- 600 * 90 * 11/3

- 1200 * 150 * 11/3

12/2 mm thickness.

- 1200 * 148 * 12/2 mm

- 1900 * 190 * 12/2 mm

- 1900 * 150 * 12/2 mm

12/3 mm thickness.

- 600 * 150 * 12/3 mm

- 900 * 120 * 12/3 mm

- 900 * 150 * 12/3 mm

- 1200 * 150 * 12/3 mm

- 1900 * 150 * 12/3 mm

- 1900 * 190 * 12/3 mm

14/3 mm thickness.

- 1200 * 150 * 14/3 mm

- 1860 * 148 * 14/3 mm

- 1860 * 190 * 14/3 mm

- 1900 * 150 * 14/3 mm

- 1900 * 190 * 14/3 mm

- 2200 * 180 * 14/3 mm

- 2200 * 240 * 14/3 mm

15/4 mm thickness.

- 1900 * 150 * 15/4 mm

- 1900 * 180 * 15/4 mm

- 1900 * 190 * 15/4 mm

- 1900 * 220 * 15/4 mm

- 2200 * 190 * 15/4 mm

- 2200 * 220 * 15/4 mm

- 2200 * 240 * 15/4 mm

- 2200 * 260 * 15/4 mm

- 2200 * 300 * 15/4 mm

20/6 mm thickness.

- 1900*190*20/6 mm

- 2200*190*20/6 mm

- 2200*220*20/6 mm

- 2200*260*20/6 mm

- 2200*300*20/6 mm

Stability and Durability:

We have discussed that multi-layer engineered wood flooring is more durable and stable than 3-layer, the main disadvantage for multi-layer is a little expensive than 3-layer, but not always, depending on material and plywood etc.

Why 3-layer floors veneer should be more than 3mm and less than 6mm?

- We think 3-4mm is the best thickness for 3-layer floors, because middle layer can support or withstand moisture and temperature changes within these ranges, too thick veneer will result in floorboard cupping, bowing or warping. Too thin veneer will leave “horizontal line” on its surface which make the whole floorboard looks ugly.

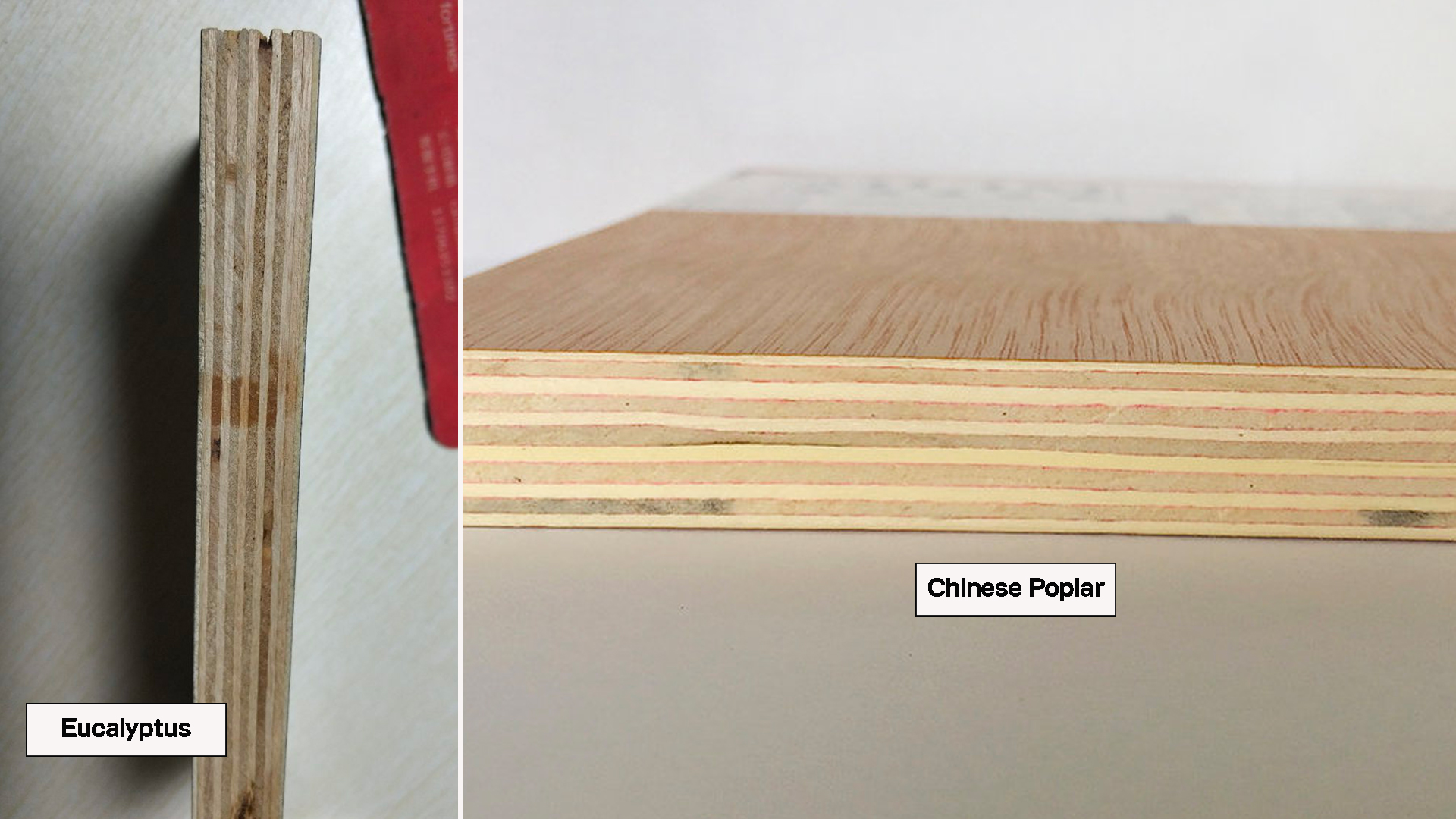

- Plywood is made from hardwood eucalyptus and birch, which are durable and stronger than pine and red fir softwood, so we recommend customers picking up multi-layer floors due to its high performance than 3-layer. There is a truth that 3-layer floors top layer wood grain runs opposite of the middle layer, and the bottom layer is the same direction as the top, this is completely same plywood structure to ensure the floor edge is strong enough to avoid breaking up.

Flooring plywood price comparison

Please note that: flooring price depends on veneer, plywood or support layer price, wood veneer grade is also influence wood flooring price, so multi-ply engineered flooring is not always cost much than 3-ply, just contact your desired suppliers first then compare with each other:

Plywood price ranks from high to low:

- Multi-ply birch plywood

- 3-layer New Zealand Pine =SPF

- Multi-layer eucalyptus plywood

- Chinese Pine

- Multi-ply Poplar Plywood

- 3-layer Chinese Poplar/Fir

Difference of these floor core layer and plywood?

1. Baltic birch plywood mainly used in multi-ply engineered floor and price is expensive these years, while it has no price advantage, you can see it often used on middle and high-end engineering projects thanks to its extremely durability, flexibility and stablity on excessive and insufficient humidity environment and its high-end look. Some customers take eucalyptus plywood as core layer and use birch as backing layer to achieve attractive look.

Price: birch plywood> eucalyptus plywood + birch backing > eucalyptus plywood.

2. SPF(spruce, pine and fir) and New Zealand pine mainly used on middle layer of 3-layer wood flooring in Europe, for example Red fir used as crossed structure same as birch plywood, bottom layer is larch, beech oak. This wood species in China is mostly used on furniture, seldom use on flooring due to customer preference, price and geographic factor etc.

3. Eucalyptus is the most popular plywood option in China because it can grow fast in poor soil and offer affordable price plus stable quality just like baltic birch. Although Eucalyptus plywood looks not as nice as birch plywood, it does work well on the market.

4. Chinese Pine, is best alternative for baltic birch plywood if you plan to buy 3-layer engineered flooring in China with similar high-end look like multi-layer engineered wood flooring with birch plywood.

5. Eucalyptus plywood density is about 600 kgs/m3, poplar plywood density is only 530 kgs/m3, Chinese poplar/fir wood is soft and it is cheap than eucalyptus. If you aim at low-end market and want to buy 3-layer engineered wood flooring from China, Chinese poplar/fir is your best option thanks to its easy accessibility and mature craft for most factories in Eastern China.

Factory distribution In China

Factories in Northeastern China mainly focus on 3-layer engineered wood flooring due to its abundant poplar, pine and Russian oak plus European oak around border between China and Russian, they can harvest with low price due to tax preference, besides, local government share prisoners and disabled people with these engineered wood flooring factories to improve local economy and low down factory manufacturing cost.

Factories in East China(Zhejiang, Jiangsu, Shanghai) specialize in multi-ply engineered flooring, because plywood first was used on furniture in Guangdong province in South China, then transfered and got wide-spread use on engineered wood flooring.