Compared with solid hardwood flooring, 2-layer and 3-layer wood flooring, multi-layers engineered wood flooring is best option when you decide to purchase wood flooring in flooring stores. One of the best advantages of multi-ply engineered wood flooring is not prone to get damage(bowing and cupping) from humid environment, but it does’t mean multi-ply engineered wood flooring is completely water-proof, when engineered oak flooring installed in places like kitchens, basements, even bathrooms, it is same as other wood flooring, it could lead to high risk of damage due to moisture in air and on floor. However, multi-ply engineered wood flooring is much better hardwood flooring, 2 layers and 3-layers wood flooring.

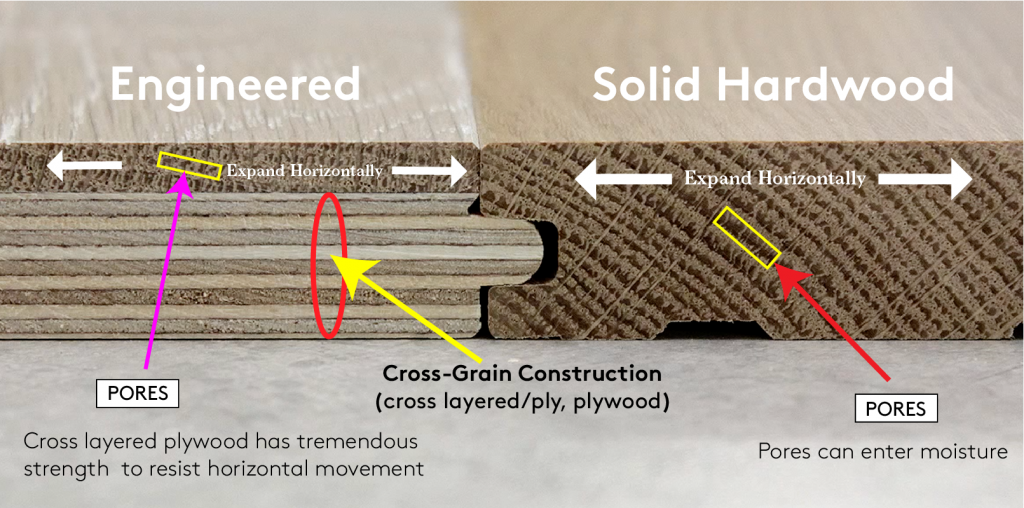

Multi-layer engineered wood flooring cross-grain construction makes it less likely to warp from temperature or moisture changes, Why? In the presence of moisture, solid wood planks will always expand across the width of the planks, rather than down the length of the boards. The advantage of cross-ply construction allows the layers to counteract each other, which will stop the plank from growing or shrinking with the changes in humidity. And most plywood is made of strong and stable wood of baltic birch, eucalyptus which it won’t change (expand or contract) as much as other plywood with weather and moisture fluctuations.

Therefore, it would be frustrating when engineered wood floor starts bowing and cupping, however, flooring brands or wood flooring factory promise that engineered wood flooring would not bow and cup before you buy it. Whatever, the most important thing that you need to do now is find the real cause of floor bowing and call flooring company to deal with and take responsibility for the matter.

1. Engineered Timber Flooring Has No Jobsite Acclimation Prior to Installation.

Acclimation is “the process of adjusting (conditioning) the moisture content of wood flooring to the environment in which it is expected to perform,” Wood is hygroscopic, meaning it expands and contracts with moisture.

Engineered wood flooring would be covered with plastic film and then be packaged in paper carton after final manufacturing process of coatings. Then it is stored in factory warehouse or directly transported to destination warehouse, so wood flooring can experience a lot of different storage environments. These spaces climate controlled area would affect the moisture content balance of the floors, absorbing moisture when the humidity is high and releasing moisture when the humidity is low. If wood flooring goes for direct installation from factory to home without acclimation, it would bow due to wood flooring transfered from low humidity area to high humidity, and it’s likely not to able to repair any more.

According to our factory experience, we recommend you buying wood flooring from flooring manufacturers thanks to good price and direct help from factory. On installation, please leave flooring in carton package(flooring packaged with plastic film) , store laying flat, packages raised off of subfloor in the home or office room where they are going to be installed for more than 7 days, so that floors can acclimate to room temperature and humidity to avoid bowing. Before installation, heating and cooling systems must be in operation for a minimum of 14 days, maintaining climate controlled area temperature inside home of 60° to 80° F degree with relative humidity(RH) of 30-50% or 35-55%, helping wood flooring in a moisture content of 6-9% or 7-11% which is optimal condition for installation in different countries. Installer should note down moisture content data through moisture content meter to ensure wood flooring is installed after acclimation and floors are not bowing.

2. Leaving Space for Expansion Gaps Around Edges or Not?

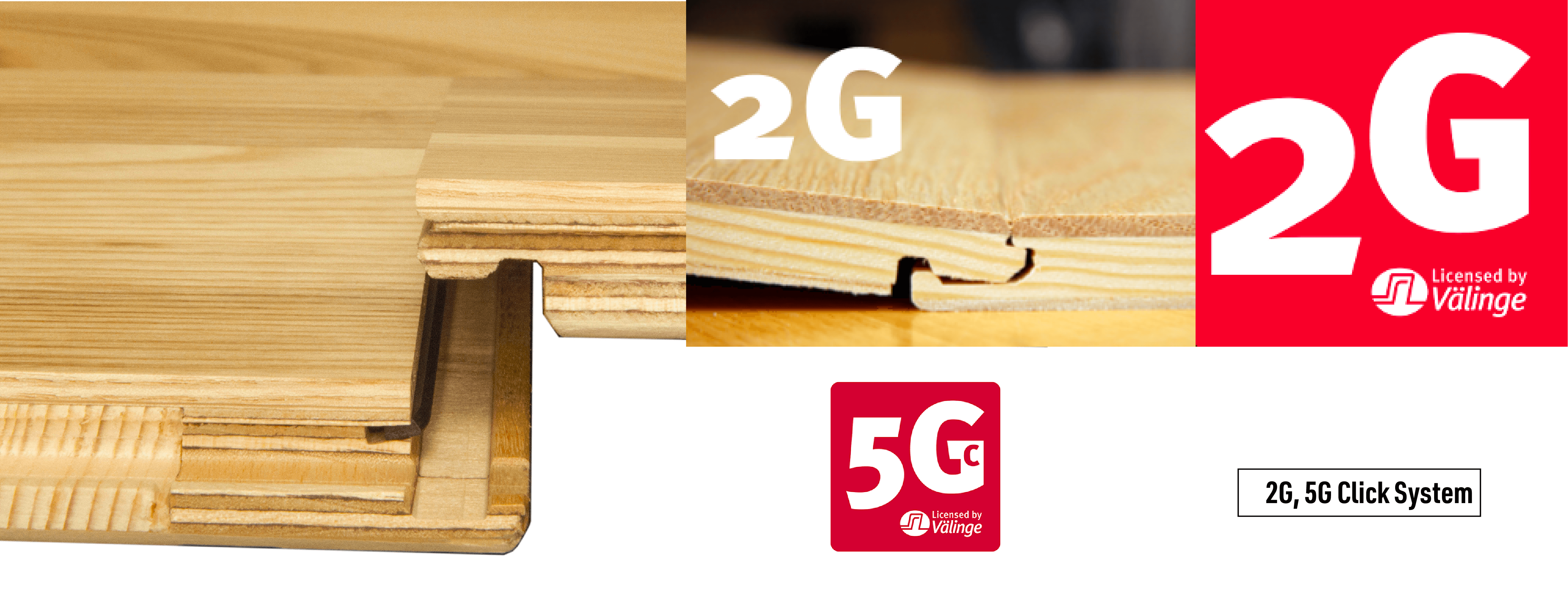

Multiply engineered oak flooring expands and contracts less than hardwood flooring products due to engineered products are created with cross-grain construction multi layers named plywood. Multi-layer engineered oak floors has tiny or none expansion and shrinkage when they are installed with method gluing down, stapling down as the cross-grain construction multi layers spontaneously restrict the movement of entire finished product itself. The exception to the rule are nailing down and floating multi-layer engineered flooring. Floating floors once installed basically become one large sheet of flooring. The entire unit will expand and contract as a whole.

It sounds confusing, is it? For example, when 190mm or 220mm wide engineered floors installed together through method of floating and nailing, these floors become a whole unit, and you will see barely noticeable expansion between each floors connected with Tongue and Groove. Thus the whole unit floors will take on or absorb moisture when the relative humidity is high, or when exposed to water. Expansion takes place, and the hardwood grows across the grain or width of the plank (see below, not all will react this way). Conversely, when air moisture levels decrease, moisture content evaporates, contraction occurs.

We have similar point and recommend professional engineered wood flooring installers leaving one quarter inch gaps for expansion at the walls or use skirting boards, we call safe “expansive gaps” which would stop floors bowing.

“Expansion gaps” are spaces left around the perimeter of rooms, against fixed objects such as columns, Measuring expansion gap thresholds, hearths, baseboard, and other stationary items built or secured into the framing structure of the home and floating.

3. Don’t Install Moisture or Vapor barrier On Subfloor or Subfloor Is High in Moisture Content

Although multiply engineered wood flooring get less expansion and contraction that solid hardwood floors, and its dimension is not stable same as ceramic tile, so DIYers ask is, “I’m installing new engineered hardwood floors on-grade, a cement slab. Do I need a moisture or vapor barrier for engineered hardwood floors?” The answer is YES!

As we know, wood can be expand and contract as climate conditions(moisture content and relative humidity) change, Moisture or vapor can cause engineered wood floors bowing, cupping, warping, and even mildew if not well treated. You must install a moisture or vapor barrier to protect your flooring from water wicking up from below. Even with an epoxy coating over the concrete, it’s best to lay down a waterproof membrane and floor underlayment, keep concrete remain 35-50% relative humidity before installation. Should a crack develop in the slab sometime in the future, the engineered oak flooring remains protected.

Despite waterproof membrane and floor underlayment can be thick and well-functioned, moisture or vapor can also pass through the concrete resulting in the floor bowing, so be careful when installing waterproof membrane and floor underlayment and engineered floors.

4. Flooring Has Been Improperly Installed.

Bowing can also occur if engineered wood flooring has been improperly installed. Lacking of adequate or sufficient wood gluing, incorrect nailing or gluing down method, plus inferior subfloor construction can all lead to wood bowing, which can come to occur as quickly as several days after installation. In all, the best way to ensure you engineered wood flooring has properly installed is to leave the job to professional flooring installation experts.

5. Engineered Oak Flooring Is Already Bowing Before Installation.

Last but not the least, sometimes you may found that engineered wood flooring already get bowed and cupped slightly when you open the flooring package. Granted, it is a defect products from client, but it’s still a a certified product, keep in mind wood is a natural product, each has its own characteristics, so slight bowing is allowed in quality system, just install these so-called defect product as a normal one and carefully connect with other floor boards then it will lie straight and smooth as an integral whole. Remember that most time floor is designed to work as an entire system with other boards snapped together with corresponding pieces. Professional flooring installation experts would glue and weigh down the outside planks to keep all floors smooth and straight, so bowing can alleviate after installation.

Of course, if you found floors bow heavily and installation experts also cannot deal with it properly, please contact flooring brands or flooring factories to solve the problem or make a reward. In general, flooring manufacturers has stock for their exported product, you can easily get stock one easily, for final solution, just communicate with flooring supplier.