Hardwood is one of the best flooring styles when you want to increase the value of your home, but it’s not for everyone. Quality planks are expensive, but there are a variety of ways you can bring the look of wood into your home if your budget is tight.

Laminate and luxury vinyl are two affordable options, but they don’t measure up to engineered hardwood. When solid hardwood is out of reach, the next best option is engineered hardwood flooring, and you might be surprised by how it’s made.

Hardwood Flooring Explained

Solid flooring has become somewhat of a rarity in the flooring world outside of hardwood, rubber, and several types of tiles. Many of the most popular styles today are made from multiple layers, which is how engineered flooring is produced.

It’s completely different from luxury vinyl and another multilayer flooring, so it’s a good idea to understand the manufacturing process behind it. Here are the layers that make up engineered flooring from top to bottom.

Engineered wood flooring is manufactured by bonding together several layers of plywood (usually from 3 to 12) which are sometimes cross-layered and subsequently glued and pressed together, thus creating an excellent core board. After being prepared, core boards are topped off with a top layer of solid wood, also known as lamella, of virtually any species of wood you want.

Finish

While you may not actually be able to see this layer, it protects your flooring from damage. That can include UV rays that cause floors to fade along with scratches and scuffs produced by daily use. There are a number of topcoats or finishes companies use on engineered flooring as well.

Popular options include oil and water-based polyurethane, although most prefinished planks are coated in aluminum oxide. While common, it is the most durable type of finish, as it can often last up to 25 years when properly maintained.

Wood Veneer

This is the layer that gives engineered hardwood its realistic appearance. That’s because companies use a veneer of real wood on these boards, and there are plenty of options to choose from. Whether you want something traditional like Oak or prefer wood from other parts of the world, there is a product out there for you.

Exotic species can bring a premium, but you can find engineered flooring made from Santos Mahogany, Bamboo, and Brazilian Walnut. The veneer also acts as another type of wear layer, but not in the traditional sense. If the veneer is thick enough, engineered flooring can be sanded or refinished, just as you would with solid hardwood flooring.

Core

This is an area where manufacturers can use different techniques, but most cores are built in the same fashion. Most cores are made from several layers of plywood, which are crisscrossed on top of one another before being bonded together. HDF and softer woods are also used in the core layer of engineered flooring, although plywood is the most common.

Base Layer

The base layer acts as the foundation of each plank. It also helps protect the core from your subfloor, and while never seen, it’s a critical part of your floor. The base layer can have a significant impact on how flooring feels underfoot, but can also determine the type of underlayment required for your installation.

How is Engineered Wood Flooring Installed?

With solid hardwood flooring, your installation choices are limited as it needs to be nailed down and is typically installed by professionals. Engineered flooring is different, as there are three ways it can be installed in homes.

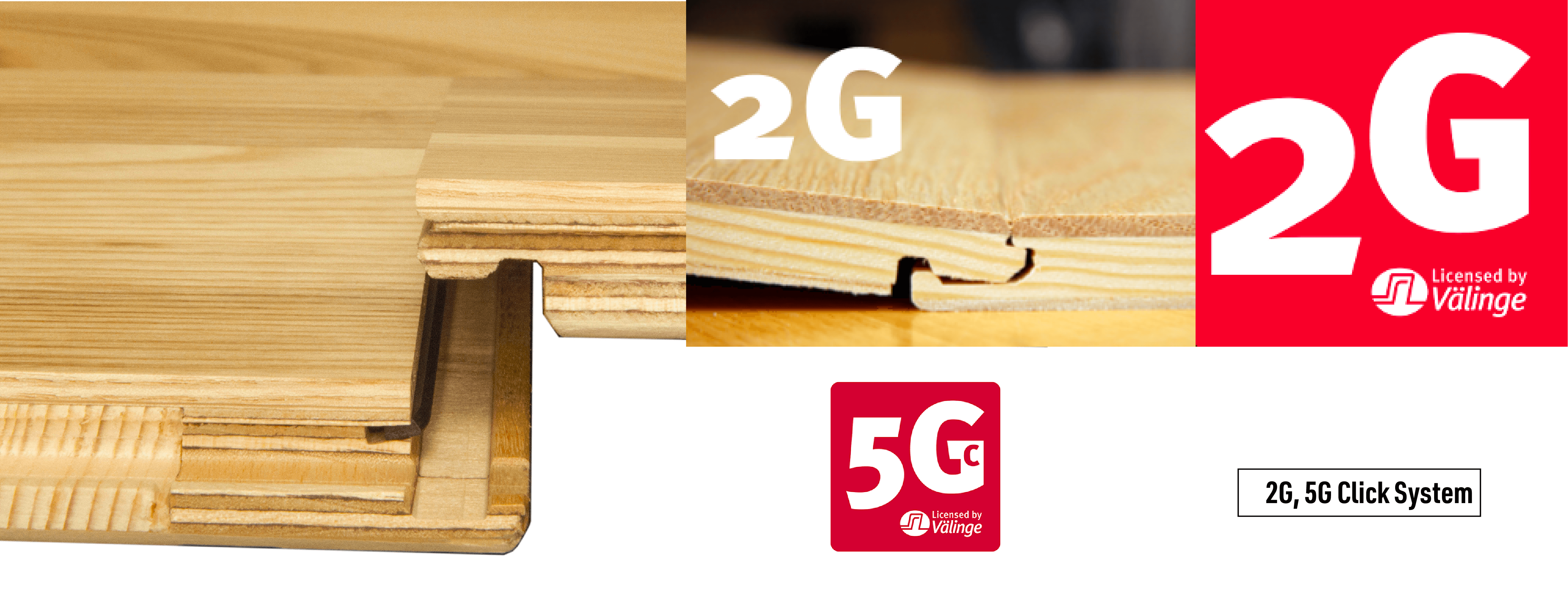

The easiest form of installation is the floating floor method. This allows you to cut boards and simply lock them into place thanks to a unique edge system. They are often referred to as click-lock planks, although some use glue as well. Click-lock boards and adhesive-only engineered flooring are the two most popular styles.

There are also manufacturers that produce engineered flooring that needs to be nailed down like traditional hardwood. These planks are often thicker and more expensive than other styles but well-worth the investment if you are installing engineered flooring over a plywood subfloor.

Engineered Hardwood Flooring Pros and Cons

Knowing the pros and cons of any flooring material is important before settling on a style, and engineered hardwood is no different. While there’s a lot to like about engineered flooring, there are still a few negatives you’ll need to consider as well.

Engineered Hardwood Pros

- Installation – Having hardwood flooring installed is expensive, but you’ll save a considerable amount of money on a professional installation if you use engineered boards. Labor isn’t as intensive unless you choose the nail down variety. If you prefer to do it yourself, installing click-lock engineered flooring is as simple as laying down a room full of LVP.

- Versatility – While we’ve seen plenty of older homes with hardwood flooring throughout the home, it’s not ideal for below-grade rooms or any area where moisture can be an issue. With the right rating, engineered planks can be installed in basements and other areas that would cause a problem with solid hardwood flooring.

- Easy to clean – Carpet can be a nightmare to keep clean, and while linoleum and sheet vinyl are easy to sweep, they can be stained. This type of flooring is among the easiest styles to clean aside from vinyl plank flooring. The best vacuum for hardwood flooring can keep your floors tidy without scattering dirt or marring them, but a broom or spray-mop will work wonders as well.

- Eco-friendly – It may seem odd to call something eco-friendly when adhesives and finishes are involved, but engineered flooring is greener than going with solid hardwood. Manufacturers only need a thin slice of wood for each plank, and some use recycled content in the core as well. That means fewer trees need to be harvested with engineered flooring.

- Variety – Whether you want grey boards with a weathered look or natural oak planks with a smooth finish, there are thousands of styles to choose from if you choose engineered hardwood flooring. There are around 20 different species available from various manufacturers, and well over a dozen color combinations as well. When you factor in finishing techniques, your options are endless.

Engineered Hardwood Flooring Cons

- Maintenance – Engineered hardwood may be easy to clean, but it’s not easy to repair if something goes wrong. Light scratches usually aren’t an issue, but if boards have a thin wear layer, the veneer can become damaged quicker than you think. You can forget sanding the damage out of budget to mid-range boards as well unless you’re willing to deal with the next negative.

- Cost – Pricing all depends on the brand and species you choose, but it’s not uncommon to find engineered hardwood priced higher than the real thing. Finishing techniques can raise the price, and so can exotic wood that would normally be unavailable in solid form. As engineered flooring doesn’t have the same ROI as solid hardwood, keep the cost in mind.

- Quality control – When engineered hardwood first burst onto the flooring scene, manufacturers began cranking out boards and breakneck speed. Quality control became an issue when companies cut corners with the cores or used off-gassing materials in the construction. It’s not as big of a problem today, but something you need to be aware of when dealing with small or unfamiliar brands.

Engineered Hardwood Flooring FAQ

Q: Can you buy unfinished engineered hardwood flooring?

A: Yes, and several companies sell high-quality flooring in this style. Finishing it yourself may not be ideal, however.

Q: Should I be concerned about VOCs with engineered hardwood flooring?

A: While it’s not the issue it once was, you can look for flooring that’s Floorscore certified if volatile organic compounds leeching into the air are a concern.

Q: How thick is the veneer on engineered hardwood flooring?

A: That all depends on the manufacturer, but on average, it ranges between 0.5 to 7mm. The thicker the veneer, the more expensive the board, although thicker planks allow for refinishing.

Q: Are engineered floors waterproof?

A: Engineered flooring does handle moisture better than solid hardwood and some other styles, but is still made from wood. While we’ve seen some products billed as waterproof, you’ll want to proceed with caution as they are still made from wood.

Q: What should the humidity level be for engineered flooring?

A: You will want to refer to the manufacturer as it can vary, but most want a relative humidity range between 30 to 50%.