This is a complete guide to engineered wood flooring understanding and buying in 2024.

So if you want to completely know and buy high quality engineered wood flooring for your residential and commercial projects, you’ll enjoy the actionable tips in this new guide.

Let’s dive right in.

Engineered Wood Flooring Fundamentals

In this Part I’ll answer the question: “What is engineered wood flooring?”.

I’ll also show you how is engineered wood flooring made and what are the pros and cons of engineered wood flooring.

Let’s get started.

What Is Engineered Wood Flooring?

Engineered wood flooring, also called engineered hardwood flooring, engineered wooden parquet flooring or tongue and groove wood flooring, different countries have different names, just like hardwood flooring being called solid hardwood flooring, wooden parquet flooring or parquet flooring, engineered oak flooring, engineered wide plank flooring, engineered chevron flooring, engineered herringbone flooring etc. Some countries calls 2-layer(multi-ply) and 3-layer engineered wood flooring. There is one cheap product made HDF + top layer engineered wood flooring.

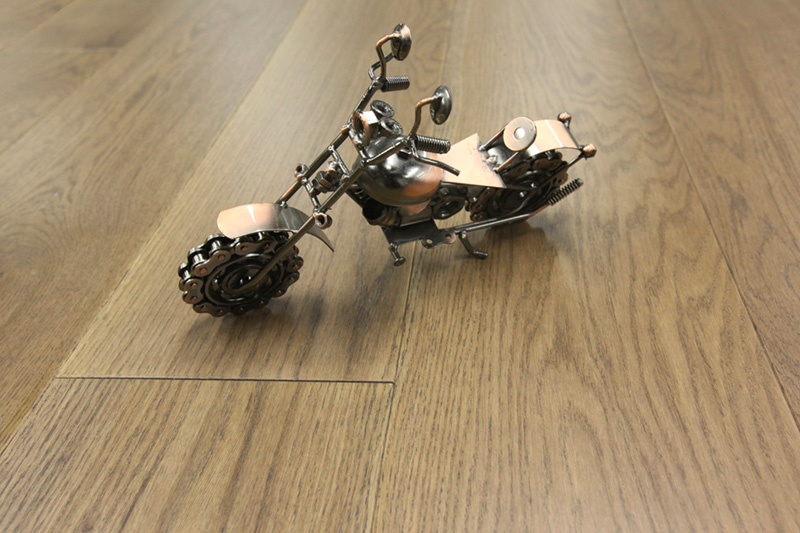

Engineered wood flooring is completely identical to the hardwood on the surface, but instead of a single wood plank, it’s made of a high-quality plywood core with a thin layer of hardwood on top.

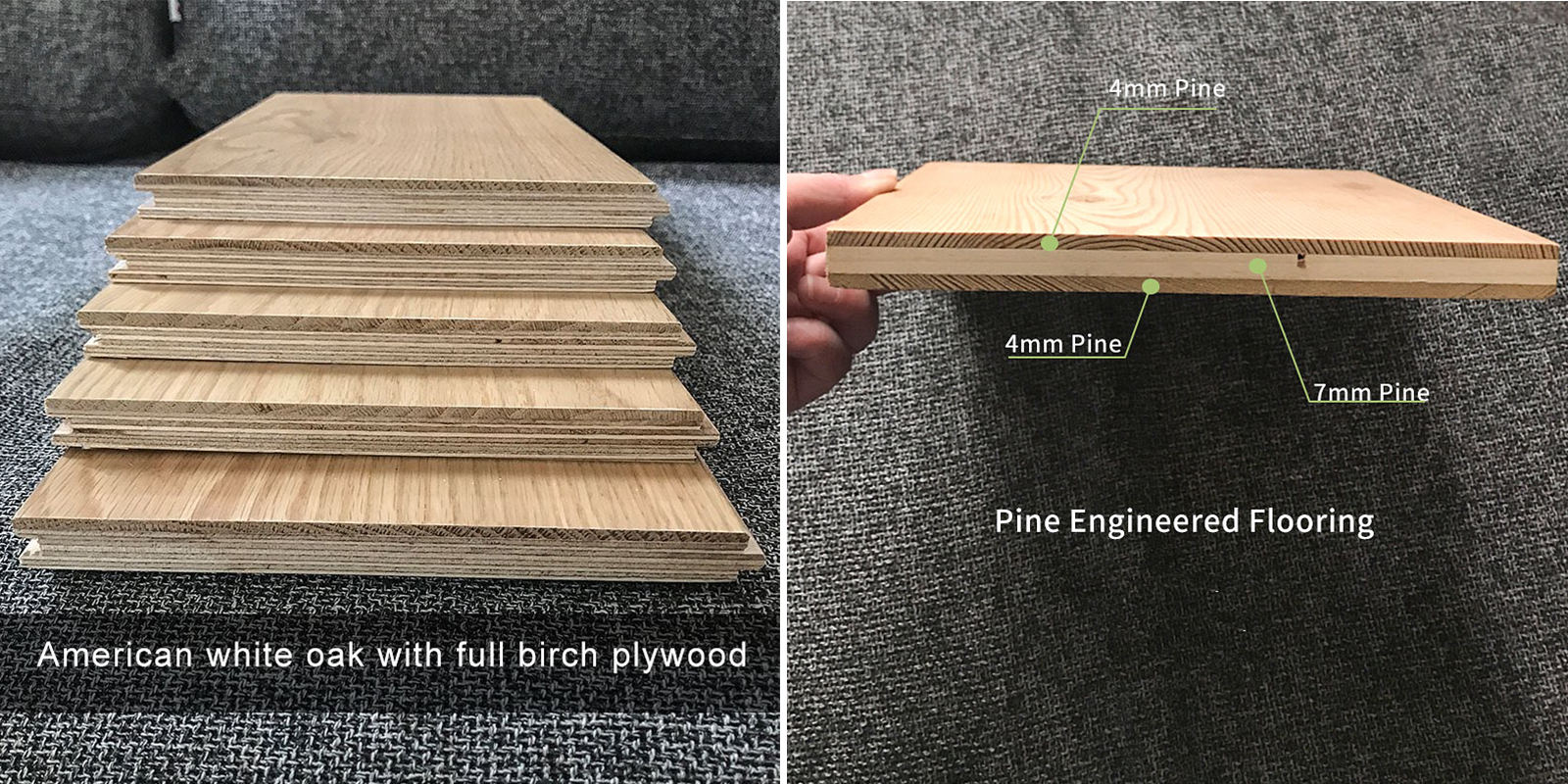

Top layer(veneer or lamella) is made of solid hardwood, such as European oak, Russian Oak, American Black Walnut, Burma Teak, ASH, Hickory and Larch, Maple, Pine. Core layer(plywood) is made of Baltic birch, eucalyptus, pine, poplar, SPF or eucalyptus plywood plus birch backing, or oriented strand board (OSB) etc.

Engineered wood lives up to its namesake as it is a product that has been “engineered” by man, not planed down from solid boards. The best way to think of an engineered flooring board is in layers as they all have a bottom, middle, and top. A thin slice or veneer of real hardwood is placed on the top of each plank and covered by a finish or topcoat for protection.

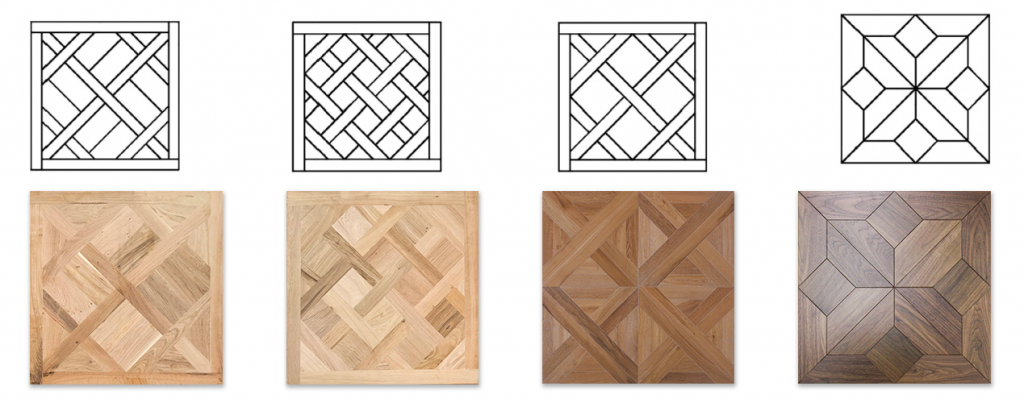

Engineered wood flooring and Solid hardwood flooring support different wood patterns: wide plank, chevron, herringbone, versailles panels and custom pattern etc. Chevron, herringbone, versailles are also called parquet flooring. Wide plank, chevron and herringbone are main trend patterns in Global market, you can see wide plank flooring everywhere.

Engineered wood flooring has two styles of structures with 3-layer and multi-ply in general. 3-layer engineered wood flooring are pretty popular in Europe, especially in Germany, Austria and France etc, Multiply is popular in Asian, North American market, you can read more difference between 3-layer and multi-ply engineered wood flooring here:

How is Engineered Wood Flooring Made?

Engineered wood flooring manufacturing process:

01. Logging

Factory imports oak and walnut logs from Europe and United States.

02. Timber Square Cutting

Logs are bandsawn into square boards.

03. Sawn cut veneer(Slice Cut)

Square boards are sawn(sliced) cut into veneers, drying and balancing moisture content of the veneer with hot pressing.

04. Veneer Sorting

Sorting veneers with different grades of A, B, C, D, E, F.

05. Kiln Drying

Sorted veneers are then well stacked for moisture balance treatment in kilns. The stacked materials(veneer and plywood) are deployment in kilns for 7 days moisture balance. Certain sizes of plywood bases require stacking and moisture balancing to induce them with suitable moisture level, an important key to ensure glued floor boards are free from bowing or bending.

06. Veneer and Plywood Gluing

Veneer and plywood are glued together with E0, E1 and hardener, CARB P2 and Japan F4 * low formaldehyde.

07. Floor board cold press or hot press

The major function of Cold press and hot press is make Veneer and Plywood Glued evenly and dry the adhesive.

08. Knots & crack repair(Epoxy Resin Filler)

Subsequent to cold press, veneered boards are transmitted to repairing department for treatment of defects in which knots and crack digging of the veneer creates rustic grade antique style flooring.The surface of the veneered board with knots and cracking are repaired by incorporating 8 colors epoxy resin as filler.

https://roxyepoxy.com/blogs/news/how-to-use-epoxy-resin-on-wood-step-by-step-guide

09. Sawn to Floor boards

The boards are transmitted through sawing machine to produce individual pieces of flooring boards.

10. Sanding Floor Boards

Flooring boards are sanded to ensure similar thickness is maintained prior to T and G profiling. The boards are simultaneously checked for thickness during this process.

11. Wire Brush

Wire brushed craft makes the wood grain more stereoscopic. And the flooring is more beautiful. The depth of brushed is 0.5-1.0mm, 1.5mm and 2mm

12. Tongue & Groove

Notching boards are checked through with Germany Homag working line to achieve precise tongue and grooves as well as micro-bevel.

13. UV Lacquer / Oil Coating

Raw flooring pieces are transmitted through coating line to produce an oiled or lacquered flooring finish. We do 7 layer (5+2) all Germany Treffert UV coating prefinished. Or Denmark Woca Natural Oil finish.

14. Flooring Packaging

Finished engineered wood floorings are packed with OEM export paper carton packaging. Flooring carton boxes are transmitted across through heat shrink plastic film to ensure waterproof packing system.

15. Wood Flooring Container Loading

Packaged cartoon boxes are neatly stacked on export pallets with all corner and sides well protected.The pallets are finally ready for container shipping. Complete product information and label is featured at the side and end part of the packages. Then load pallets into container and ship to the destination port.

01) Engineered Wooden Parquet Flooring Manufacturing Process Video:

02) Engineered Wood Plank, Chevron, Herringbone Flooring Manufacturing Process Video:

What Are Advantages and Disadvantages of Engineered Wood Flooring?

Compared to solid hardwood flooring sensitive to moisture and temperature change, engineered wood flooring is much more eco-friendly with less wood dust, cost-effective, durable, moisture and temperature resistant, less maintenance and easy installation. The best quality engineered wood flooring same as hardwood flooring, will give your living space a unique design, amazing appearance, beautiful look and luxury feeling, as an professional engineered wood flooring manufacturer and parquet flooring solution provider we think you’ll be surprised some of the options available.

There are a wide variety of types of flooring you can use in a residential property and commercial buildings, such as laminate, SPC, vinyl, marble and carpet floors, and each has its own strengths and weaknesses. As popular as engineered wood is, there are a few drawbacks you’ll need to be aware of after we take a look at the advantages.

Engineered Wood Flooring Pros

1.Cost-effective:

Compared to solid hardwood flooring, engineered wood flooring is cheaper with same species, dimension, wood grade and joint system. For example, engineered oak wide plank is cheaper than solid oak wide plank flooring in generally, but if the thickness exceeds a certain value, the price may be similar. The veneer(lamella) industry thickness is 2 to 6 millimeters, with a thicker wear layer generally indicating a more premium product, now in many countries, brands and retailers are selling wear layer less than 2mm due to fierce market competition and customers care more about cost itself, and veneer with 1.2mm thickness has been a standard on local market, please note that the thicker veneer, the more expensive the engineered wood flooring is.

And have you ever dreamed of getting exotic hardwood floors of African mahogany, tigerwood, Brazilian Cherry throughout your home and office? Now you can live up your dream with durable and cost-effective engineered wood flooring. While African mahogany, tigerwood and Brazilian Cherry hardwood flooring get pricy, but the engineered mahogany, tigerwood and Cherry flooring cost drops considerably when there is only a sliver on top layer with eucalyptus, pine, SPF and birch plywood core and backing. Needless to say, if you want something special in tropical, engineered flooring is the best alternative and pretty good price with much better function of temperature, moisture and humidity resistance.

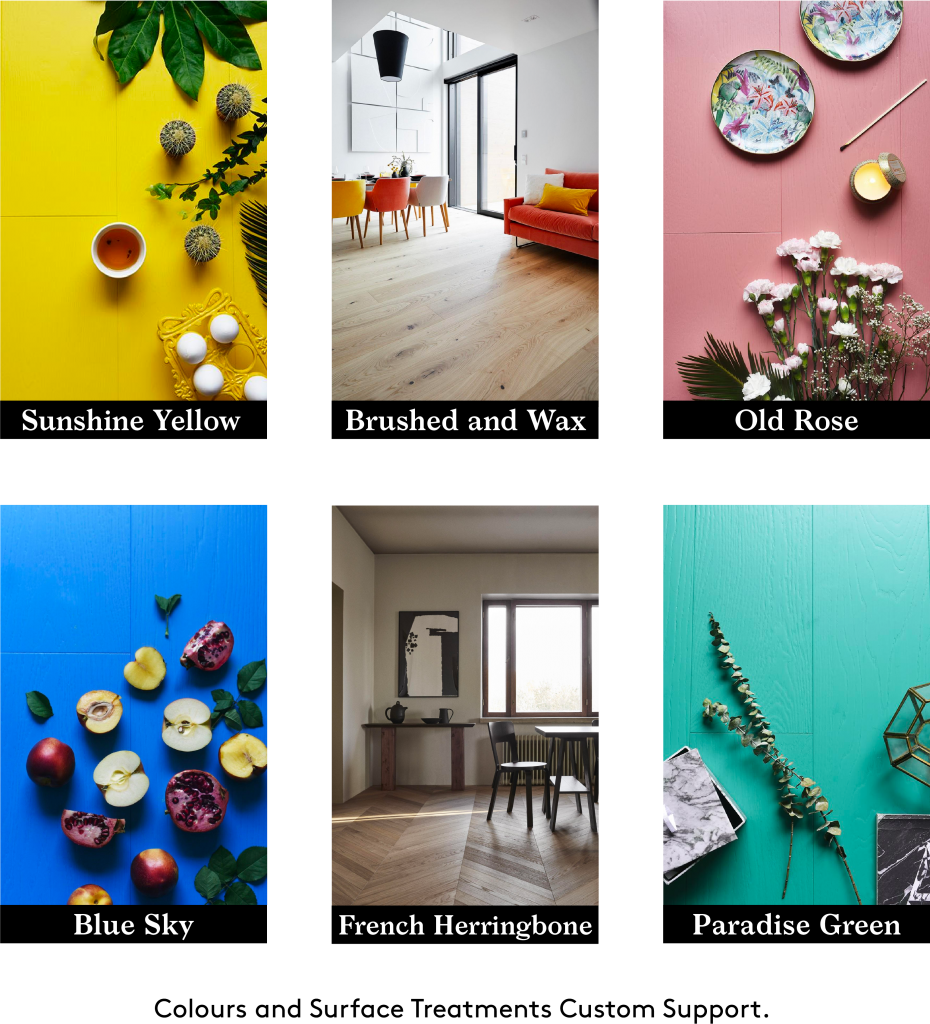

2. Stylish with Amazing Appearance:

You can also get access to dozens of wood species with engineered wood flooring on wear layer same as solid hardwood flooring. Besides, you can also get a number of different finishes, which make engineered wood flooring looks incredibly stylish, you can get any colours your want.

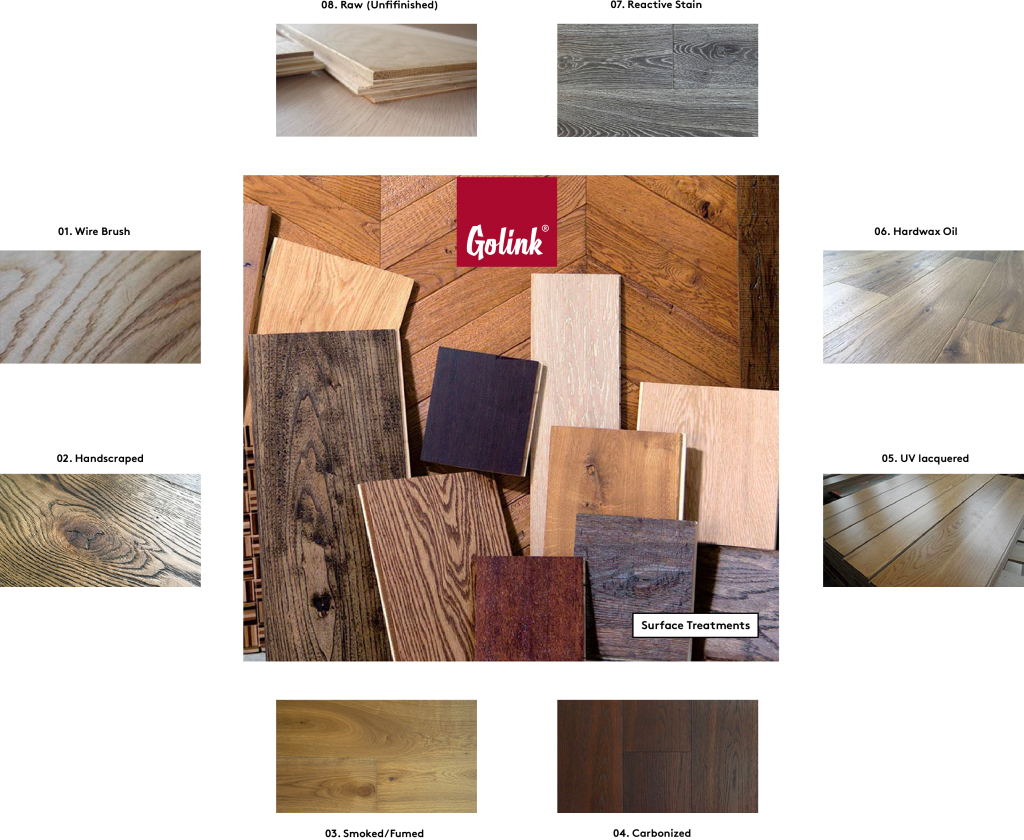

01. Wire Brush

Brush is a simple way to see some nylon brusher to take out the soft part of the wood and make the grain highlighted.

02. Handscraped

Handcraft including edge distressed/handscrape/collapse knots/crack repair & bandsaw marks etc.. In order to feature the natural characteristic of the flooring to get an ages feeling.

03. Smoked/Fumed

We use Amonia to get reaction of the Tannic Acid in the oak to get a infiltrating color change from the bottom to the top of the veneer rather than strain them. With smoked flooring we can get some extremely wonderful colors by using some other pigment staining in lacquer or oil.

04. Carbonized

Carbonize is an organic substance to make the wood into carbon like through heat treatment in kiln or distructive distillation. In this process the wood is become dark and most of fiber in grain was broken but still keeps the appearance. This is a way to get the wood adapt to outdoor use or sometime just for getting some certain color according to designer’s idea.

05. UV lacquered

The lacquer can make floor have more hard & wear- resistance surface and be adjustable in glossy level. We use Germany Treffert aluminum oxide water-based lacquer to give flooring a durable and strong surface.

06. Hardwax Oil

Oil can give the floor a thin coating for a simple protection and more important is it gives the wooden floor a natural appearance without any gloss.

We use many different brand of oil including Woca, Loba, Rubio Monocoat et..

We can make both lacquer & oiled flooring in a wide variety of customized colors.

07. Reactive Stain

Chemical reaction is made by the certain special formula with using the reaction of some Acidi/Alkaline reagent and the Tannic Acid in Oak.

The color of the Oak floor will get subtle changing from the inside of the wood and since the different volume of Tannic Acid in each piece of Oak, the color shades of the floor gets natural & unique.

08. Raw(Unfinished)

Customer can also buy our unfinished but features & defects well repaired engineered wood flooring offering a 180 grid sanded surface for an easy onsite coating procedure.

The main appeal of hardwood flooring is its timeless look and that is something you will also get with an engineered wooden flooring. Engineered oak flooring is by far the most popular wood floor, this comes in a multitude of finishes and colours.

Please read more colours here:

3. Temperature & Moisture Resistance

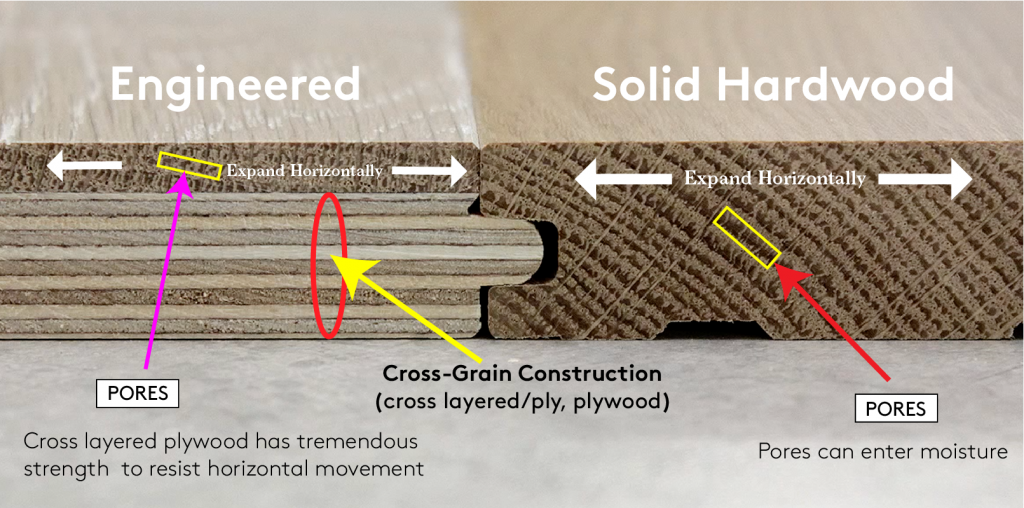

Engineered wood flooring cross-grain construction makes it less likely to warp from temperature or moisture changes, Why? In the presence of moisture, solid wood planks will always expand across the width of the planks, rather than down the length of the boards. The advantage of cross-ply construction allows the layers to counteract each other, which will stop the plank from growing or shrinking with the changes in humidity. And most plywood is made of strong and stable wood of baltic birch, eucalyptus which it won’t change (expand or contract) as much as other plywood with weather and moisture fluctuations.

Solid hardwood less stability than engineered wood flooring is because solid hardwood has more pores where moisture can enter and only one way to expand horizontally resulting in cupped and buckled, however, engineered floor on the other hand has a cross-ply plywood core providing tremendous strength to resist horizontal movement and engineered floor also has far fewer pores than the solid hardwood flooring resulting in a product that performs exceptionally well, especially with wider planks. Although engineered hardwood wood flooring can withstand changes in temperature and moisture better than solid wood floors, they still need an expansion gap to allow for small movements when installation.

4. Easy Installation

Engineered wood flooring is much more easy and better to install on concrete subfloors and works well with radiant floor heating systems than solid hardwood flooring due to its cross-ply construction which is more resistant to temperature and humidity change. Besides, engineered wood flooring can be easily installed with types of joint systems of staples, nails, gluing, click, floating and even “lock” together, making it really helpful for beginners first buying engineered wood floors for residential project and installed by themselves(DIY projects). Although click-lock joint system engineered wood flooring is expensive than tongue & groove flooring, generally expensive 1-3 USD/sqm, but the tongue & groove flooring need professional installers which would be much more pricy than engineered wood flooring click-lock engineered wood flooring installed by yourself or hire a professional worker for help.

4. ECO Friendly

Engineered wood flooring top layer – veneer made with hardwood is thiner than solid hardwood flooring total thickness, and the trees, such as oak, walnut, teak used for solid hardwood and engineered wood wear layer grow much more slowly than those used to make engineered wood flooring plywood, so choosing engineered wood flooring would help save more exotic trees and low wood flooring cost, besides, veneer cut with slicing produce no dust wood and also not waste wood.

5. Adding Value to Home

Home and office will add more value if decorated with wood flooring, especially installed with exotic hardwood flooring, this is a wise tactic people employ to increase their home’s value, upgrade quality of life, increase value of house resale. Engineered wood flooring with thick wear layer will also make the same thing come true and is a great way to add some extra long-term value to your property. Even if you aren’t looking to sell right now engineered hardwood flooring can be an investment for the future, because people will pay a premium for “the good stuff” even if it isn’t really any better.

Engineered Wood Flooring Cons

1. Expensive Compared to Non-Wooden Flooring

Compared to solid hardwood flooring, engineered wood flooring is cost-effective, but it is really expensive than flooring options, like vinyl flooring, carpet, SPC, laminate and tile etc.

2. Bad Quality With Bad Raw Materials and Glue

Not all engineered flooring factory create same good quality products. Some manufacturers use very cheap and bad raw materials and not eco-friendly glues to produce wood flooring to get more profit. It looks almost same as good quality product on surface but end up being very weak, unstable and harmful to people’s health after just a short time, the EPA has found that low-quality engineered wood flooring is sometimes made with glue that contains formaldehyde, a volatile organic compound (VOC) that goes through an off-gassing process once it’s installed in your home. So be sure to do research on engineered flooring manufacturers and their products before you make your selection to buy products from them. You can ask what glue that engineered wood flooring manufacturer use, most factories in China use Franklin E1, E0 glues, and some manufacturers also offer F4* low formaldehyde Plywood base to meet Japan clients requirement.

3. Fading Problem

Fading is not a big problem for people if they know how to maintenance wooden flooring, customers can buy engineered wood flooring treated with UV-resistant coatings on the surface, but the most important thing is that make sure to keep your floors out of direct contact with sunlight, keep curtains & blinds closed or use area rugs to cover vulnerable areas of floor.

4. Scratched and Dented

This is a big con that engineered wood flooring shares with hardwood flooring, even though engineered wood is more durable and stable than hardwood flooring, it still dent and scratch easily over time. And from the floor test, we can see the thicker the wear layer, the more easily engineered floor gets dented and damaged.

A Definitive Guide to Buying Engineered Wood Flooring

Understanding what engineered wood flooring is and the difference between engineered wood flooring and hardwood flooring, plus their pros and cons can bring to your interior design is one important part of engineered wood flooring selection. There are several areas that you need to take carefully consideration before you get started jumping into measuring the area of house and picking up the wood flooring color that you may like.

As an engineered wood flooring manufacturer, we will ask clients what wood species, wood grade, size, colors, joint system they need when our clients inquire us for the flooring price.

Why? Most people have no idea what colors, size, wood species do they need, and it’s likely they also don’t know much about wood grades, or they may never hear about it.

So, let’s take a look at wood species, plywood material, wood grade, flooring size, price.

Species

If you like hardwood flooring most, such as oak wood flooring, Black Walnut, Hickory, Pine, Larch, Merbau, Doussie, Ash hardwood flooring, engineered wood flooring is a best alternative for you, you can easily find engineered wood flooring with oak veneer that is same as surface of oak hardwood flooring, so if you are fond of exotic hardwood flooring with high price, then engineered wood flooring is your best choice with offering same distinct look and better price.

Which wood species are most used for engineered wood flooring?

Oak is the most popular wood species used for wood flooring, European oak is is among the most popular choices for engineered wood flooring. Oak is considered among the most durable wood floors and can last for generations.

In North America, Maple and Hickory are two of the most popular wood species used on wood flooring due to property of cost-effective, rich source across United States and Canada. Walnut and Cherry are a little more pricy than Oak, Maple and Hickory, but Black Walnut and Cherry look more high-end than Oak, Maple and Hickory, the biggest problem for Walnut and Cherry wood flooring is that you will have to deal with darkening over time with the latter. Beech and Birch engineered flooring are popular in Northern Europe, birch are normally used on plywood due to its durability and short growth cycle which can low the engineered wood flooring price and improve the quality of engineered wood flooring. Even though Beech and Birch are less used for veneer but also an excellent choice if you want something unique and stylish.

Engineered bamboo flooring is also a budget-friendly option for your home, it offers some unique properties of easier to install, sustainable and good with moisture exposure. However, it does not last as long as oak, walnut, teak, hickory and maple wood flooring, and also not offer much variation in color and shade.

Now, Acacia gets more and more popular in recent years than IPE, Walnut, exotic wood species of Tigerwood and Brazilian Cherry, but it is still a small part of wood flooring market, just same as parquet flooring. In a word, you can find most kinds of engineered wood flooring in China with competitive price, whatever you like 2 ply, 3 ply and multiply flooring with different wood species on top layer.

Plywood

Plywood is the core of engineered wood flooring, it’s the basement of wood flooring. Eucalyptus and Birch(Baltic Birch and Russian Birch) are the two main wood species used for plywood in China, you can also find Pine, Poplar, SPF used on the manufacturing of engineered wood flooring. Eucalyptus and birch are almost same price as Oak in China, so engineered oak wood flooring is not cheaper than oak hardwood flooring in some time. Why eucalyptus are popular as plywood materials in China? Firstly, eucalyptus tree doesn’t require much upkeep, it grows very quickly, and it doesn’t consume many resources either. This quick growth rate and sustainability help make it fairly eco-friendly. Birch is the most stability option, The Baltic birch tree originates in the Baltic States – Estonia, Latvia and Lithuania. Baltic birch plywood is primarily produced in Finland and Russia. Some manufacturers claim Baltic Birch is the only plywood core that can be used for under floor heating, however, Eucalyptus also support according to our research and practical usage feedback. In all, birch plywood is mainly used on high wood grade engineered wood flooring, such as AB, ABC grades.

Birch Plywood thickness generally support 6mm, 9mm, 12mm, 15mm, some manufacturers support thickness with 11mm, 14mm, 16mm, 18mm. So engineered wood flooring total thickness is veneer thickness + plywood thickness.

How to choose between eucalyptus and birch plywood when you decide to buy engineered wood flooring? And which one is better?

According to our sales figures, both plywoods are good, but if you want to get a high end feeling and much more stable wood flooring with adequate budget, birch plywood is your best choice and the only plywood core that can be used for under floor heating. Eucalyptus plywood is also good option because it is the most popular plywood being used in China with stable quality and competitive price and it look more nice than Poplar.

Surface Treatments

Surface Treatments also means Surface Finishes. Surface treatments is one of the important part when you take engineered flooring into consideration for your project. Most factories support surface treatments as we list below:

01. Wire Brush

02. Handscraped

03. Smoked/Fumed

04. Carbonized

05. UV lacquered

06. Hardwax Oil

07. Reactive Stain

08. Raw(Unfinished)

(1) European Oak, 4mm Sawn Cut Veneer, Fumed/Smoked, UV Lacquered, White Washed Case:

European Oak, Character(ABCD Grade), 1mm Eased Bevel, 1900*190*15/4mm.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(2) European Oak, 4mm Sawn Cut Veneer, Brushed Carbonized, UV Lacquered Case:

European Oak, Natural & Character(ABCD Grade), 1900*190*15/4mm, 12.5% (400-1500mm) Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(3) Russian Oak, 3mm Sawn Cut Veneer, Invisible UV Lacquered Prefinished Case:

Russian Oak, ABC & D+ Grade, 1900*190*14/3mm, 12.5% (400-1500mm) Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(4) Russian Oak, 3mm Sawn Cut Veneer, Natural Color, Wire Brushed, UV Lacquered Prefinished Case:

Russian Oak, ABC Grade, 1900*190*15/3mm, 12.5% (400-1500mm) Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(5) Russian Oak, 4mm Sawn Cut Veneer, Brushed & Chemical Reaction, BONA Industrial Lacquer Case:

Russian Oak, Natural & Rustic (ABCDE), 2200*240*14/4mm, 12.5% (400-1800mm) Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(6) European Oak, 2mm Sliced Cut Veneer, UV Lacquered, Wire-Brushed Case:

European Oak, Character (ABCD), 1900*190*12/2mm, 1mm Eased Bevel, 12.5% (400-1500mm) Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(7) American White Oak, 3mm Sawn-Cut Veneer, Bona UV Coating Case:

American White Oak, Natural & Rustic (ABCD), 1900*190*14/3mm, 0.5mm Micro Bevel, 4 Side Tongue & Groove.

American Franklin Phenolic adhesive, E0 standard 100% Russian Birch Plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(8) European Oak, 5mm Sawn Cut Veneer, Burn Edge, UV Oiled, Denmark Woca Oil Prefinished Cases:

European Oak, Rustic (CD), 1900*190*20/5mm, 2mm Full Bevel, 12.5%(400-1500)mm Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(9) European Oak Brushed, 6mm Sawn Cut Veneer, Chemical Treatment & UV Lacquered Cases:

European Oak, Character(ABCD), 1900*180*18/6mm, 2mm Full Bevel, 25%(400-1500)mm Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

(10) European Oak, 6mm Sawn Cut Veneer, Smoked & Woca Oil Cases:

European Oak, Character(ABCD), 1900*180*18/6mm, 25%(400-1500)mm Random Length.

American Franklin Phenolic adhesive, E0 standard Eucalyptus plywood Available for Radiant Heat, 3 weeks moisture balance for stability.

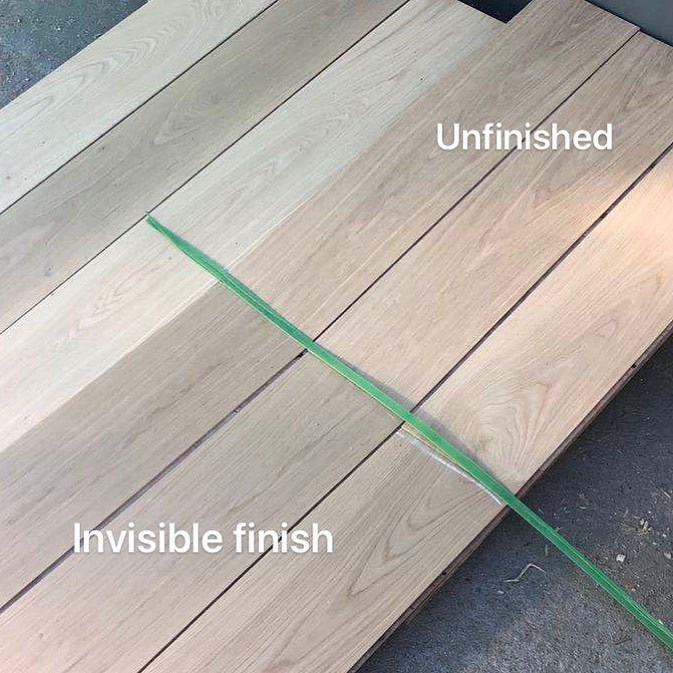

Although you can buy engineered hardwood flooring with prefinished and unfinished options depending on your demand and preference. However, prefinished engineered wood flooring is still the main trend for consumers because of ease installation and convenience, but for manufacturers from Europe, North America, Australia, they would also import unfinished(Raw) engineered wood flooring from China to low cost(in most case, prefinished and raw wood flooring are almost same price), because they can re-treat the surface in local factories and sell to local retailers for flexibility and customizability, so if you carefully check people’s demands and analysis market, you can find a certain amount of engineered wood flooring manufacturers offering unfinished engineered wood flooring.

A perfect way to check for invisible coating good or not is to use the same board to do half finish half unfinished to compare. The best result is both of them looks same.

As for finishes coatings, some customers think Aluminum Oxide is the best from a durability standpoint and found on flooring in the budget and premium classes, but some others Vice Versa, they think Aluminum Oxide Prefinished flooring is one of the worst finishes for a residential environment. Despite the perceived “hardness” of this finish, floors finished with aluminum oxide will get scratches and they cannot be touched up so their beauty deteriorates rapidly! In fact, floors with this Aluminum Oxide finish generally carry a 25-year guarantee, but it’s not something you can do yourself, it’s a “factory” finish that’s built to last. Acid-cured and Moisture-cured finishes are also extremely durable, but something professionals handle, and materials that produce high VOCs. That means you’ll have to evacuate your home for a week or more, whereas a hard-wax oil isn’t as toxic and allows you to stay put.

Oil-based Polyurethanes are cheap, easy to apply, and popular. They can yellow with age, however and like many finishes, release VOCs. Water-based polyurethanes are much easier to deal with all-around but aren’t quite as durable as the other options.

In a nutshell, if you plan to finish the floors yourself, you’ll want to look into each type of finish and consider its durability compared to the amount of VOCs it releases. Prefinished boards are highly recommended, as the savings from going the DIY route may not be as significant as you think.

Clear finish is a great way to show off the natural beauty of your wood flooring. It doesn’t alter or change the tone of the wood but can highlight grain patterns and color streaks while providing protection. You can also get textured, distressed, or smooth wood – something we covered in our ultimate hardwood flooring guide.

Engineered Wood Flooring Surface Treatments & Common Colors List:

| No. | Treatments & Colors |

|---|---|

| 01 | UV Lacquered |

| 02 | UV Lacquered, White Washed |

| 03 | UV Lacquered Prefinished as Raw |

| 04 | Brushed, Carbonized, UV Lacquered |

| 05 | Fumed/Smoked, UV Lacquered, White Washed |

| 06 | Brushed & Chemical Reaction, BONA Industrial Lacquer |

| 07 | Brushed & Chemical Reaction, UV Lacquer Coating |

| 08 | UV Lacquered, Wire-Brushed |

| 09 | Bona UV Coating |

| 10 | Light Brushed, Edge Damaged, Grind Knots, Surface Embossed, Loba Natural Oil Finished |

| 11 | Light Brushed, Arc-shaped Ease Bevel, Depression, Loba Natural Oil |

| 12 | Medium Brushed, Edge Distressed, Hollows, Loba Natural Oil |

| 13 | Fumed/Smoked, Wire Brushed |

| 14 | Burn Edge, Natural Oiled |

| 15 | Burn surface, Hand-scraped, UV Lacquered, Wire-Brushed |

| 16 | Burn Edge, UV Oiled |

| 17 | Fumed/Smoked, Hand-scraped, UV Lacquered, Wire-Brushed |

| 18 | Fumed/Smoked, Hand-scraped, White oiled, Wire-Brushed |

| 19 | Depressed Defect, Edge Damage, Embossed, Hardwax Oiled |

| 20 | Fumed/Smoked, UV Oiled, Wire-Brushed |

| 21 | Medium Brushed, Dark Stain UV Lacquered Finish |

| 22 | Light Smoked, Brushed, UV Lacquered White Washed |

| 23 | Smoked & Woca Oil |

| 24 | Brushed, Chemical treatment & UV Lacquered |

| 25 | Brushed, Light Smoked, UV Lacquered White Washed |

| 26 | Grey Washed with UV Lacquered |

| 27 | Brushed, Light Smoked, UV Lacquered |

| 28 | Smoked, Light Brushed Extra Matt UV Lacquered |

| 29 | Brushed, UV Lacquered |

| 30 | Smoked, Brushed, UV Lacquered |

Coating Used On Prefinished Flooring Details.

Anti-scratched UV Lacquer prefinished flooring: In general, most wood flooring manufacturers use Germany Treffert Aluminium Oxide(Al2O3) Anti-scratched UV lacquer coating to achieve Lacquered flooring.

Germany Treffert UV Lacquers are free of Halogenated Hydrocarbons, Heavy Metals, Herbicides, Pesticides, Formaldehyde, and any harmful emissions.

Normally factories do 7 layers and 9 layers.

- 7 Layers with 5 layers bottom lacquer coating and 2 layers top lacquer coating.

- 9 Layers with 7 layers bottom lacquer coating and 2 layers top lacquer coating.

| Product Mark No. | Product Description |

|---|---|

| 4713310000 | Water Based UV Adhesive |

| 6113400000 | UV Transparent Putty |

| 6113580000 | UV Putty |

| 6613021000 | UV White Bottom Lacquer Coating |

| 6613600000 | UV Bottom Lacquer for Sanding |

| 6613420000 | UV Transparent Bottom Lacquer |

| 6613470000 | UV Anti-Scratched Bottom Lacquer |

| 6613310000 | UV Repairing Stuff |

| 6613321000 | HPC UV Anti-Scratched Surface Coating 10°Matt |

| 6613329000 | HPC UV Anti-Scratched Surface Coating 90°Glossy |

| 6613371000 | UV Super Matt Varnish |

Natural Oiled and UV Oiled Flooring Details.

Denmark WOCA Oil Flooring:

| Product Mark No. | Product Description | Color | Glossy |

|---|---|---|---|

| 401 | Water Based Stuff | / | / |

| 501 | UV Bottom Oil | Natural Color | / |

| 506 | UV Bottom Oil | Natural color | / |

| 507 | UV Face Oil | Natural color | 8% – 12% |

| 508 | UV Face Oil | Natural color | 5% – 8% |

| 601 | UV Face Oil | 5% White Pigment | / |

| 603 | UV Bottom Oil | 2.5% White Pigment | / |

| 605 | UV Face Oil | 5% White Pigment | 12% – 18% |

| 606 | UV Face Oil | 2.5% White Pigment | 12% – 18% |

| 1503 | Natural Oil | / | / |

Size:

Engineered wood flooring often has three styles with Plank, Chevron, Herringbone, Plank is one of the most popular one on the market, size or dimension is one easy mistake that beginners make when they plan to pick up engineered wood flooring. Engineered wood flooring or solid hardwood flooring don’t have nice uniform pattern due to their “variable length”, it also where the term “parquet” comes into play, and it’s something that you are going to hear often when you on the market of solid hardwood flooring or engineered wood flooring. “Parquet” is a general term in flooring which sources from France, now it not only means wood flooring, but also indicates style of wood flooring of Chevron, Herringbone and square parquet etc..

Square Parquet Patterns

Widths vary from one wood flooring manufacturer to the next, although there are standards factories stick to.

Engineered Wood Flooring Common Specifications:

- Length: 400 – 5000mm,

- Width: 70 – 450mm,

- Thickness: 8 – 20mm,

- Wear Layer Oak: 1.2 – 6mm.

| Length(mm) | Width(mm) | Thickness(mm) | Veneer(mm) |

|---|---|---|---|

| 490 | 70 | 10 | 3 |

| 600 | 90 | 10 | 3 |

| 600 | 125 | 14 | 3 |

| 900 | 125 | 15 | 4 |

| 1200 | 150 | 14 | 3 |

| 1900 | 190 | 14 | 3 |

| 2200 | 220 | 15 | 4 |

| 2200 | 260 | 18 | 4 |

| 2200 | 300 | 18 | 4 |

| 4000 | 300 | 20 | 6 |

| 5000 | 400 | 20 | 6 |

Engineered Wood Flooring Oak Grades

The main types of wood grades as defined by the National Hardwood Lumber Association are (from least defects to most defects):

- Firsts and Seconds

- FAS One Face Select

- # 1 Common

- # 2A Common

- # 2B Common

- $ 3A Common

Most of these grades are used for furniture, but sometimes you’ll see this terminology applied to wood flooring.

Wood veneer(Oak, Black Walnut and Teak etc.) are well sorted with Grade A(Clear), Grade B(Select), Grade C(#2 Common), Grade D(Cabin/Shop), Grade E(Rustic), Grade F in engineered wood flooring factories.

Understanding how hardwood is graded can be difficult for beginners and experienced ones, unlike the grades you got in school, hardwood grades don’t reflect a scale of quality A to F. Instead, wood grades are identifiers to provide a quick reference for a floor’s visible natural character, because there are multiple variations within one class (clear, select and best, #1 common, #2 common etc.) , so let’s take a look at details of each wood grade to know how to choose the best wood grade you like most:

A Grade – Clear – 1st Grade:

No knots or other defects in the wood, this classification is considered the premium part within each wood, little variation in color and exceptional average board length.

B Grade – Select – 2nd Grade:

A notch below the best, the appearance have more ‘looks’ of wood from color streaks to broken grains, etc.. Minimal character markings, and average overall length. The most widely used grade for hardwood floors.

C Grade – #1 Common / Character / Natural:

These boards have bigger open knots to some splits with a rougher overall texture, also some sapwood. Character markings such as small knots and mineral streaks. Moderate color variation between sapwood and heartwood. Small average length per board.

D Grade – #2 Common Cabin / Shop:

There will be more natural defects such as bigger knots, worn holes sapwood, color vierations. Significant manufacturing marks and character marks. Prominent color variation between sapwood and heartwood. Short overall length.

E Grade – Rustic:

The wood is full of natural defects and big splits. Which need a lot of repairing work to make it useful.

Warranty and Durability

Warranty is one of the most concerned things for buyers, but it is pretty transparent and straightforward in the engineered wood flooring industry, you can get warranties from 10 to 30 years if you buy direct from local reputable retails or dealers. From wood flooring manufacturers point, warrant is not a big problem, because wood flooring has been a fairly mature industry and you can get any kinds of wood flooring from shop and online market, however, there are several points that you still need to keep in mind, for example, wood veneer and wood flooring surface treatments: coatings or finishes. As we talk above, coatings and veneer thickness determine the lifespan of the flooring.

As engineered wood flooring manufacturers, we recommend our clients picking up veneer more than 2mm with prefinished coatings, thicker veneers allow terminal customers to refinish and sand your floor a handful of times, which can further extend its lifespan. Prefinished coating flooring would help you low the maintenance cost and improve the flooring quality and stability. If you are in a competitive market, veneer with thickness of 1 to 2mm would be your best options, which could help you attract more customers due to cheap price and high turnover rate.

Cost

When pricing engineered wood, you’ll see that most is sold by the square foot even though it’s sold by the case, pallet, and box. Cost is also something that varies wildly depending on whether you plan to go the budget route or want the best engineered flooring money can buy. Our table will give you a rough idea of what to expect from these common wood species…

| Wood Species | Mohawk | Somerset | Shawfloors | Armstrong | Bruce |

|---|---|---|---|---|---|

| Oak | $3.50 – $6.76 | $4.85 – $9.00 | $4.02 – $9.88 | $3.69 – $7.09 | $3.59 – $9.88 |

| Maple | $4.32 – $7.56 | $6.50 – $9.55 | $4.02 – $9.88 | $4.69 – $7.49 | $4.19 – $6.49 |

| Hickory | $5.02 – $5.68 | $6.75 – $12.40 | $4.02 – $9.88 | $6.09 – $8.09 | $4.19 – $5.79 |

| Black Walnut | $5.02 – $5.68 | $9.00 – $10.00 | N/A | $6.09 – $8.09 | $5.39 – $5.79 |

| Cherry | N/A | N/A | N/A | $6.08 – $6.70 | $5.19 – $6.46 |

| Wood Species | USfloors | Eco-Fusion | Hursthard Woods | Cali Bamboo | BellaWood |

|---|---|---|---|---|---|

| Acacia | $3.95-$5.49 | $6.97-$7.39 | $3.79-$3.99 | N/A | $5.69-$6.09 |

| Bamboo | $5.47-$7.43 | $4.39-$4.99 | N/A | $3.99-$6.31 | N/A |

| Brazilian Cherry | $5.47-$7.43 | N/A | $3.89-$6.19 | N/A | $5.39-$5.79 |

| Brazilian Walnut(IPE) | N/A | N/A | $3.49-$7.49 | N/A | $5.29-$8.99 |

| Tigerwood | N/A | N/A | $4.29-$6.99 | N/A | N/A |

| Bloodwood | N/A | N/A | N/A | N/A | $11.59-$11.99 |

| Heart Pine | N/A | N/A | N/A | N/A | N/A |

| Eucalyptus | N/A | N/A | N/A | $5.99-$6.42 | N/A |

| Cork | $4.61-$5.62 | N/A | N/A | $5.08-$6.21 | N/A |

Best Engineered Hardwood Flooring Brands

Best Engineered Wood Flooring Brands – USA

- Anderson Tuftex

- Bruce

- Johnson Hardwood

- Kährs

- Mohawk

- Pergo

- Shaw

- Somerset

Compared to solid hardwood or linoleum, engineered wood flooring is something you can find with ease. Local hardware stores may have it in stock, and you’ll be blown away by the varieties available through larger shops like Lowes and Home Depot. With that in mind, here are a few quick reviews on some of the top brands that specialize in producing engineered flooring.

Somerset Hardwood Flooring

Somerset Hardwood Flooring’s products carry the Manufactured in the USA label, and they specialize in Appalachian hardwoods. While you won’t find any exotic species of trees in their lineup, they have an excellent range of engineered flooring if you prefer Oak, Hickory, and Maple.

This company currently has six collections to choose from with Hand Crafted, Classic, Character, Specialty, Wide Plank, and Color Plank. Each collection is a little different from the rest, so there is something for everyone. If you like the look of hand scraped wood with lots of texture, the Hand Crafted lineup may suit your needs. It’s available in Oak, Maple, and Hickory while the Classic collection only uses Oak and is textured, but not scraped.

Consumers that want a rustic vibe will like the Character collection, which shows the natural beauty of knot holes in Hickory, Maple, or Oak. The Wide Plank series is self-explanatory as is the Specialty class with its random width boards. There are well over 30 colors between all the collections, and their SolidPlus engineered boards are suitable for below grade rooms as well.

All of Somerset’s engineered flooring has a 50-year finish warranty along with a lifetime structural guarantee. Commercial usage cuts that number to only 5 years which is standard, and you can sand their flooring at least once thanks to a thick wear layer on top.

Harris Wood Floors

Harris is one of the older companies on our list. Founded in 1898, they have been dealing with wood for a long time, and have churned out engineered flooring since the 80s. With over a dozen series available, they should be one of your first stops when you prefer design and colors over exotic species.

Harris’s hardwood flooring is available in two styles with Tongue & Groove or Engineered Click. Their selection is easy to navigate as well as you can shop by species, color, treatment, or width. Treatments vary by series but include smooth or textured finishes while the available widths range from 3” to 7.5” wide planks.

You won’t find any IPE or Bloodwood at Harris, but they do have all the popular domestic species including red & white Oak, Hickory, Maple, and Walnut. They also have some harder to find wood like Cherry, pecan, and yellow birch. Colors range from light and natural to dark hues and smoky greys. In addition to hardwood, the company also carries a small line of engineered cork flooring.

Whether you prefer the Hickory Shadewood from the Aspen collection or Yellow Birch Wheat from SpringLoc TODAY, Harris has a solid selection of flooring and plenty of colors to choose from. The warranties vary by line, but you can expect a 25-year finish warranty at a minimum, and all their boards come with a lifetime structural guarantee for residential use.

Lauzon Flooring

This Canadian company is one of the leaders in hardwood flooring and one of the greener brands as well. They use sustainable forest management and selective harvesting practices with all of their products, which includes domestic species along with a few exotic kinds of wood.

Lauzon decided to keep things simple, so there are only three collections, although there are 12 series overall. The Designer collection is their top product and features both domestic and exotic species in a variety of shades. Hard Maple, Hickory, and Oak are present along with Brazilian Cherry and Santos Mahogany. You also get the best warranty from all the tiers at 35 years.

Ambiance is their mid-range tier with a 30-year guarantee, but it also happens to be their largest collection with the widest variety of shades. It’s all domestic species, however, and the same goes for the Essential collection. It’s their budget tier, and one with some interesting choices like Character grade Cape Code red Oak and Chai Tea hard Maple. While we don’t have a price on these planks, they come with a 25-year warranty and an aluminum oxide finish.

Lauzon has some of the more unique colorways, and we like the fact they have grades like select & better or character on some of their products as well if you are looking for something different. Their top two lines are treated with a Titanium finish, and some series feature their Pure Genius tech, an air-purifying material built into the finish.

Other Alternatives

While those are just a few companies that produce engineered flooring, you can expect to find products from most of the top flooring manufacturers as well. Shaw, Armstrong, Mullican, and Mohawk all have at least one engineered wood lineup, but they also make everything from carpet to linoleum instead of focusing on wood.

Another company that falls into that category for different reasons is Miseno. They have everything from cabinet hardware to lighting but also carry a very nice array of engineered flooring featuring some of the harder woods. Are you partial to Bamboo? Well, Cali Bamboo is the best place to look into that style of flooring, but they also carry eucalyptus, Hickory, Oak, and Maple.

US Floors is another company that carries Bamboo and cork, along with some interesting products like COREtec. You can find both their products and Cali Bamboo’s through Lowes along with brands like Bruce and Shaw. If you prefer Home Depot, you can find a massive selection of engineered hardwood from Heritage Mill, Home Legend, Bruce and Malibu Wide Plank.

Engineered Flooring FAQ

Q: Can I use spray mops or wet mop engineered hardwood flooring?

A: This is an area where you’ll need to check with the manufacturer on specific product lines. In most cases, using a spray mop on water-resistant engineered boards is acceptable, but wet mops, steam mops, and other cleaning tools could void your warranty or potentially damage your flooring.

Q: How many times can I refinish new engineered flooring?

A: It all depends on how thick it is. Budget-friendly boards typically can’t be refinished, and you may only be able to sand thick engineered hardwood flooring once or twice.

Q: Is a thicker wear layer always better?

A: If you have heavy traffic in your home, paying extra for a product with a thick wear layer can be well worth it. Too thick of wear layer can hide the beauty of the wood below if the right balance isn’t maintained, however.

Q: Can I install engineered flooring in basements or an attic?

A: Yes. One of the advantages of engineered hardwood is its ability to work in areas that aren’t ideal for solid hardwood installations. That includes below-grade rooms like basements and humid areas like attics, although you need to make sure the product is rated for those areas beforehand.

Q: What’s the best way to clean engineered hardwood flooring?

A: For pet hair and dirt, a broom will suffice or a dust mop for light-duty cleaning. Vacuums that work on solid hardwood or LVP are also suitable for engineered planks, but you’ll want to check the cleaning instructions before using liquid cleaners on your flooring.

Q: Is engineered flooring easy to repair if it becomes damaged?

A: It depends on the extent of the damage and how the flooring was installed. There are a number of ways to deal with light scratches, but chips or serious damage may require a board to be replaced. That can be relatively easy with click-lock flooring, but it’s not so simple with planks that have been glued down.

Q: Is it possible to stain engineered flooring if I get tired of the color?

A: That’s usually not a feasible option, although unfinished engineered hardwood flooring is available if you prefer to customize the color of your flooring in your home.

Q: What’s the easiest type of engineered flooring to install myself?

A: Any type of engineered flooring that has a click-lock edge system. This allows you to piece the floor together like a giant puzzle, which makes installation a breeze for most homeowners.